Line Loss

Line Loss

Is the erosion of voltage over a long distance caused by the resistance of the feeder cables. The severity of line loss increases with the amount of current carried by a particular conductor, but generally line loss starts to become apparent in feeder cables longer than 100ft. As a rule of thumb, electricians assume that most feeder cable loses about 4 v per 100 ft when running at 80% capacity.

Causes of Line Loss

- Distance: the resistance of a conductor increases directly with its length. the longer the run, the greater the line loss.

- Thickness of Cable: The resistance of a conductor decreases in proportion to its cross-sectional area. the larger the conductor, the less the linen loss.

- Amount of amperage: Voltage drop varier directly with the load. The larger the amperage load, the larger the line loss.

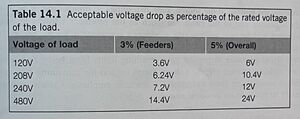

Acceptable Voltage Drop

Is the amount of voltage drop that still allows acceptable performance from the equipment, and does not cause harm to the equipment. To not exceed 3% will provide "reasonable efficiency of operation."

Mitigating Line Loss

Increasing Voltage

Do not exceed increasing the voltage more than 5%.

- Generator: Larger generators, like a tow plant have a voltage adjust knob.

- Transformers: step down transformers have voltage adjust knob that allows you to adjust the voltage in 2.5% increments.

Two things to keep in mind when adjusting the voltage to mitigate line loss

- Equipment at the upstream end of the cable run can be over voltated, because distance is less from the power source.

- Voltage drop is proportional to amperage load. when you turn off a big light or two the load will be reduced siginificantly and theirfore less line loss and voltage will be high for the equipment still being powered and can cause damage to the equipment.

There are better safer ways to mitigate line loss than increasing voltage at the source. The Ultimate way to mitigate line loss is to add more copper to the system, ei. thicker cable and more lines of thicker cable in very large systems.

Line Loss Calculations

The equations below are for single phase loads only. There are special equations for three phase loads, but the equipment that requires that type of power are rare. Knowing certain aspects of the power system we can use math to figure out

- Thickness of cable needed to limit the voltage drop to a selected percentage

- Distance a particular cable can carry a known amperage

- Exact voltage drop for a particular cable at a stated amperage

- Maximum current we can send through a given length of cable and not exceed a chosen voltage drop.

Defining the variables

- L = The length of the wire in feet. This is the one-way distance from source to load. (Note that in the equations, this number is multplied by 2 to get the two-way distance the current has to flow to complete the circuit)

- Vd = The voltage Drop from source to load

- I = The current carried by the cable, or amperage.

- K = the specific resistance of the material composing a conductor. For copper cable, K - 10.8 at 25 degrees C. Usually k and 2 are combined in the equations 2k = 21.6.

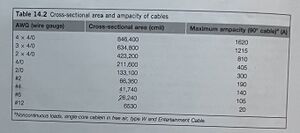

- Cm = The cross-sectional area of a wire measured in cirular mils (cmil). These tend to be pretty big numbers.

* 1 mil = 1/1000 in.

* cmil = (diameter in mils)Squared

Cable Types and Their Guage

- #12 - Stinger

- #10 - Twistlok

- #6 - 60a bates

- #4 - 100a bates

- #2 - banded